Your Rapid Response Partner For Mission Critical Sheet Metal Fabrication.

3 Types of Metal Bending

Sheet metal bending is a process whereby the end product is a single piece of sheet metal that is no longer flat. It may have a single bend or multiple bends. The bend(s) may be different radius's from sharp 90 degree bends with large 2" - 12" radius's that create a more rounded and softer edge.Read More

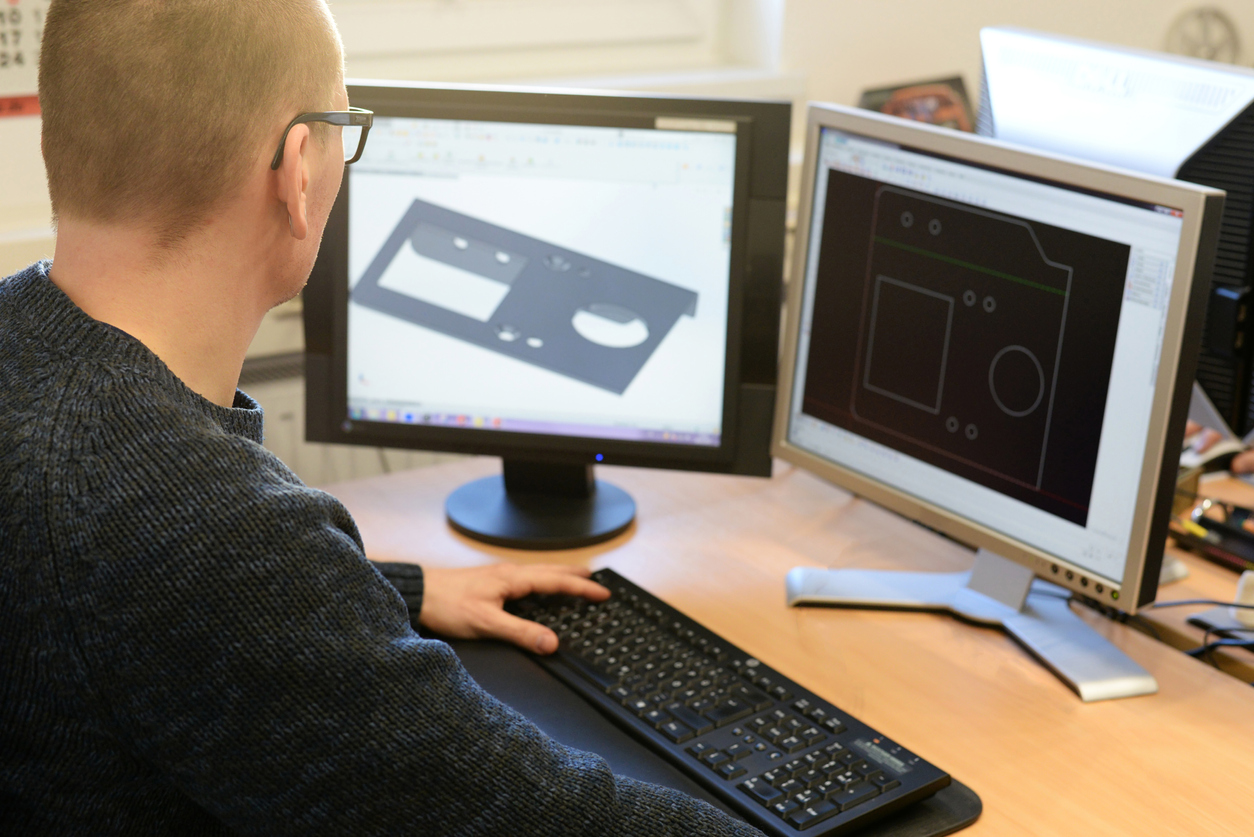

7 ways to improve tolerances to make better parts

Sheet metal tolerances describe the acceptable deviation between features on sheet metal parts to ensure correct and consistent fit in installation or integration. Read More

5 Benefits of Outsourcing Your Sheet Metal Fabrication

Determining whether it makes sense to outsource your sheet metal fabrication can be a daunting task and there are important questions to answer. Things to consider include, but no limited to, - estimated annual part(s) volume, complexity of part(s), etc....Read More

3 Advantages of Robotic Welding vs. Manual Welding

Robotic welding was initially developed in the late 1970's in Japan and found its way to America in the early 1980's. Those robotic welders were very specialized and not very common to see. Today's robotic welders are quite different from their earlier ancestors, which is a good thing. As popular as robotic welding has become, manual welding is still quite prevalent.Read More

4 Types of Metal Finishes

Metal finishing is an essential process for producing strong, high-quality metallic products. This is especially true for specialized metal parts that require specific chemical, electrical, or tarnish resistances.Read More

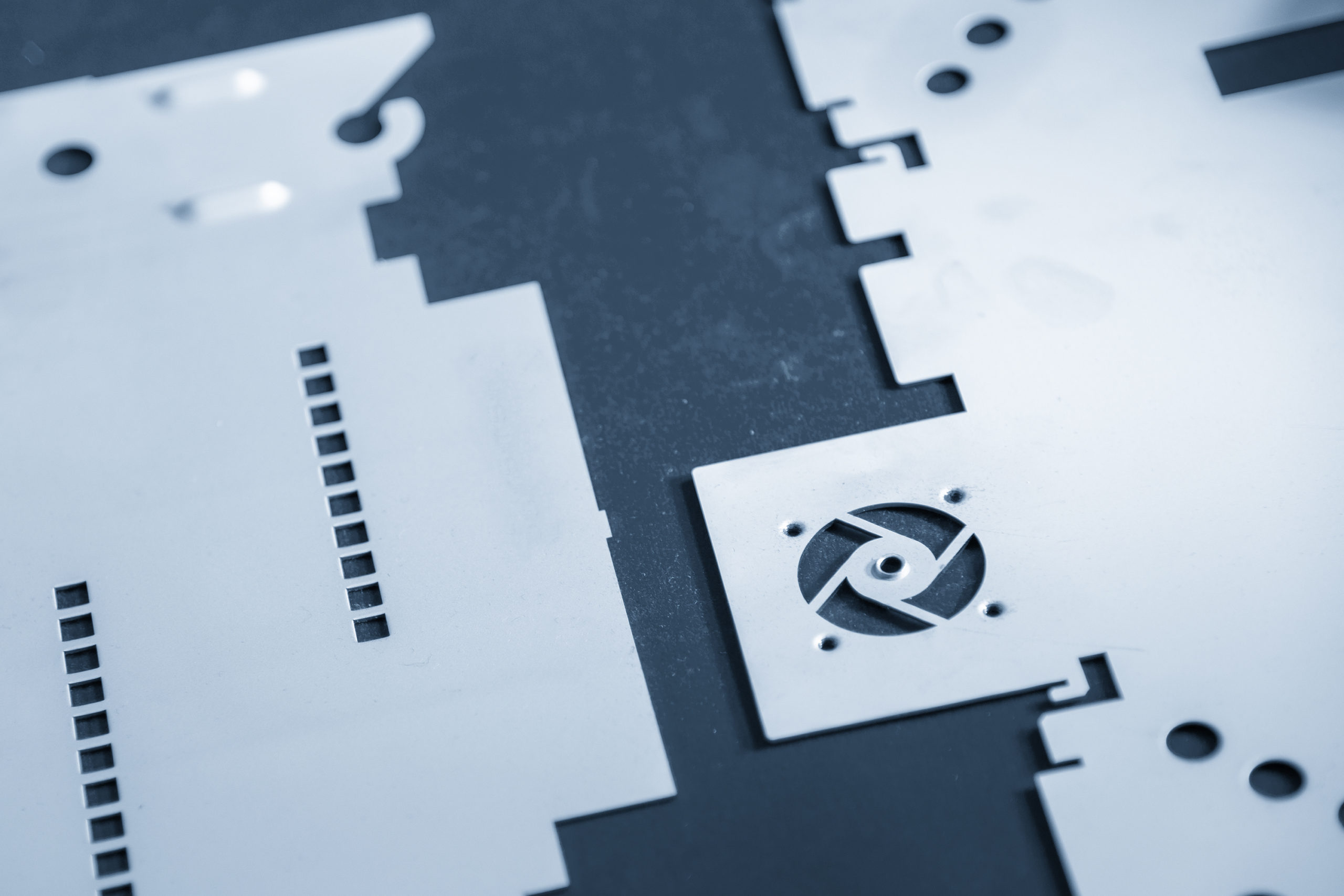

Laser Cutting vs. Punching

The first step of a precision sheet metal part is cutting, which generally is either laser cutting or a punching. The part itself will generally dictate which process is more ideal and most efficient.Read More